Micro Structure

Material No. . UNS System (ASTM): C11000

Chemical Composition

| Element | ||

|---|---|---|

| Cu(1,2,3) | ||

| Min (%) | 99.9 | |

- Oxygen and trace elements may vary depending on the process.

- This is a high conductivity copper which has, in the annealed condition a minimum conductivity of 100% IACS.

- Cu value includes Ag.

Mechanical Properties

| Form | Tensile Strength In Mpa | Elongation In % | Hardness in Vickers-HV | Conductivity at 20°C |

|---|---|---|---|---|

| Rod | 220-390 | > 10% | 60/120 | >98.3 |

| Flat | 220-390 | > 10% | 60/120 | >98.3 |

| Profile | 220-390 | > 10% | 60/120 | >98.3 |

| SC Ring | >200 | >35 | > 40 | >98.3 |

| Tube | - | - | >60 | >98.3 |

| Block | - | - | >60 | >98.3 |

Physical Properties

| Melting Point – Liquidus °C | 1083 |

| Melting Point – Solidus °C | 1065 |

| Density lb/cu in. at 20°C | 0.322(1) |

| Specific Gravity | 8.91 |

| Electrical Conductivity% IACS at 20°C | 101(2) |

| Thermal Conductivity Btu/ sq ft/ ft hr/ °C at 20°C | 226 |

| Coefficient of Thermal Expansion 20 – 100 10⁻⁶ per °C (20 – 100°C) 9.4 | 9.4 |

| Coefficient of Thermal Expansion 20 – 200 10⁻⁶ per °C (20 – 200°C) | 9.6 |

| Coefficient of Thermal Expansion 20 – 300 10⁻⁶ per °C (20 – 300°C) | 9.8 |

| Specific Heat Capacity Btu/ lb /°C at 20°C | 0.092 |

| Modulus of Elasticity in Tension ksi | 17000 |

| Modulus of Rigidity ksi | 6400 |

| (1) Actual value .321 - .323. (2) Volume and weight basis. |

|

Thermal Properties

| Treatment | Minimum* | Maximum* | |||

|---|---|---|---|---|---|

| Annealing | 371 | 649 | |||

| Hot Treatment | 760 | 871 | |||

| * Temperature is Measured in Celsius. | |||||

Fabrication Properties

| Technique | Stability |

|---|---|

| Brazing | Good |

| Butt Weld | Good |

| Capacity for Being Cold Worked | Excellent |

| Capacity for Being Hot Formed | Excellent |

| Coated Metal Arc Welding | Not Recommended |

| Forgeability Rating | 65 |

| Gas Shielded Arc Welding | Fair |

| Machinability Rating | 20 |

| Oxyacetylene Welding | Not Recommended |

| Seam Weld | Not Recommended |

| Soldering | Excellent |

| Spot Weld | Not Recommended |

General Fabrication Processes

- Forging

- Extruding

- Drawing

- Cold working

- Hot working

- Ring Rolling

- Bending

- Machining

Applicable Form

| Form | Description |

|---|---|

| Rod | Hot Extruded & Cold Drawn Copper Rod |

| Flat | Hot Extruded & Cold Drawn Copper (Bar, Strips) |

| Profile | Hot Extruded & Cold Drawn Copper Cut to length |

| Wheel | Forged and Machined |

| Tube | Hot Extruded Tube & Machined |

| Block | Forged & Machined |

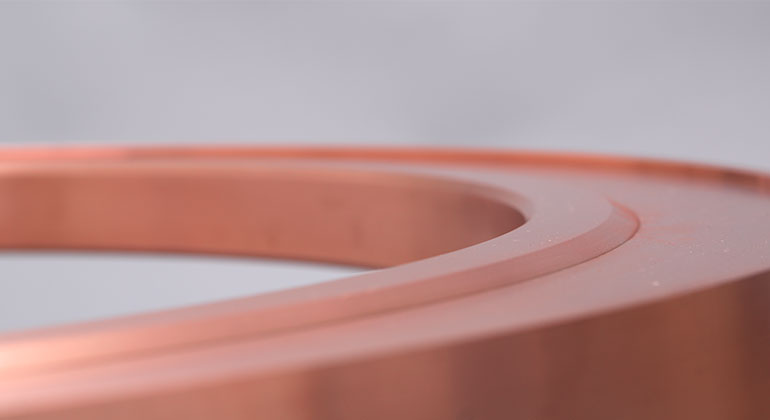

| Ring | Forged, Rolled & Machined |

Typical Uses / Application

| Product Category | Product | Reason |

|---|---|---|

| Electrical | Busbars | Electrical Conductivity, Thermal Conductivity, Corrosion Resistance |

| Conductors, Electrical | Electrical Conductivity, Thermal Conductivity, Corrosion Resistance | |

| Contacts | Electrical Conductivity, Thermal Conductivity, Corrosion Resistance, Solderability | |

| Switches | Electrical Conductivity, Thermal Conductivity, Corrosion Resistance, Solderability | |

| Conductors, Electrical | Electrical Conductivity, Thermal Conductivity, Corrosion Resistance | |

| Industrial | Anodes | Electrical Conductivity |

| Short Circuit Ring | Electrical Conductivity, Thermal Conductivity |

Copyrights © 2019 Modison Copper Pvt Ltd | All Rights Reserved.

Site By Spenta Digital