We build products that fulfill your needs. At Alumayer Inisa, we offer services to architects and planners in all areas and in all stages of construction. Our engineers offer extensive know-how and cumulative experience in system development, planning and production that meet the project specifications.

As every new project has its own particular technical requirements, its ability to stimulate and receive ideas and concepts to and from other countries and through its in house design and R&D department ensures that Alumayer walling technology will remain at the forefront in the market place.

In the past 50 years, we have delivered most challenging tasks of complex structures and high-rise installation with highest level of standards and managing complex supply chain issues.

Our facility is equipped with systems and process for 3D modelling as well as Thermal Anlaysis. We are experts in implementing Thermal Brake Systems as well.

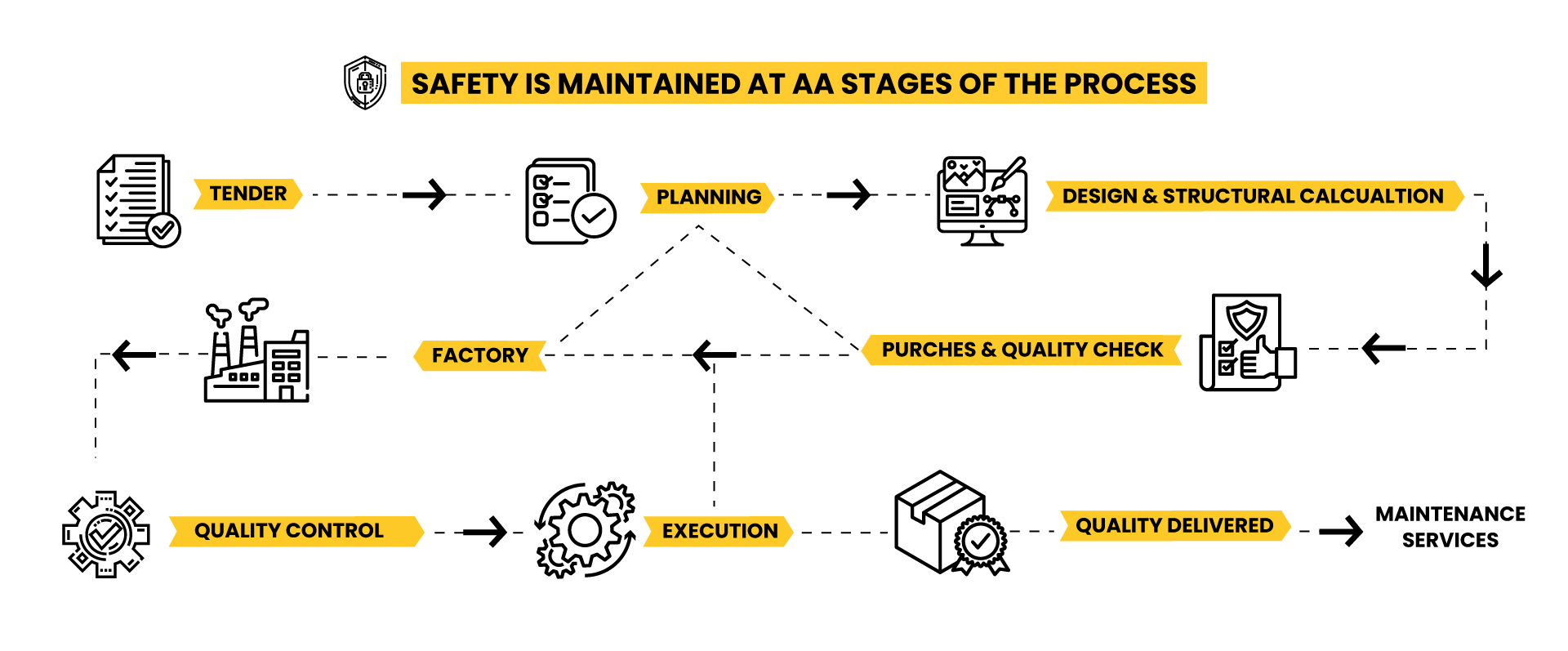

We pride ourselves in delivering quality products with system level quality checks in committed time.

We are among India largest manufacturing facilities equipped with the latest imported machinery and technology.

We offer highly customised design systems and development across the world.

Our process begins with a design and engineering team in collaboration with architects, consultants, general contractors, and clients to bring to life the most iconic projects. We integrate our bespoke design systems with structural design capabilities to include risk assessment and mitigation, designs to resist extreme loadings, protection from blast etc. All our systems are built in-house and unique to Alumayer. We create unique design solutions based on the clients requirements

The data mentioned above is on an annual basis (one shift) and can be doubled depending on project requirements.

Our state of the art machinery is imported to help us deliver cutting-edge solutions to our clients in India & abroad.

Close to one of India's biggest ports - JNPT, the factory is situated in Patalganga near Mumbai,

our production facility is one of the biggest in India spread over 390,000 sq. ft.

At Alumayer, we have devised an in-house testing rig in the manufacturing facility to test and assess the capability and performance of components for industrial use as per project specifications. Visual mockup provisions are being availablre for better end product clients to assess.

We at Alumayer India are proud to have developed bespoke systems in-house for all types of facade requirements. Most of our clients prefere indigeniously developed systems while we are also certified by leading system providers like Schuco, Alumil etc

Our team of designers and engineers are well trained to develop solutions using advanced softwares for designing and production.

Our design team consists of 10+ members who are skilled and trained to develop systems to offer best solutions to our clients.

For our export clients, we are experts in dealing with certified system suppliers like Schueco, Wicona, Alumil, Technal etc.

Indigenously developed systems by in-house designers and engineers

Our in house design team consists of 60+ highly skilled design experts who are trained and led by senior industry experts from India & Israel, to develop systems to offer best solutions to our clients.new

We at Alumayer India are proud to have developed bespoke systems in-house for all types of facade requirements.

Most of our clients prefere indigeniously developed systems while we are also certified by leading system providers like Schuco, Alumil etc neew

Logistics is the main and most challenging task in the facade industry. At Alumayer India, the complex logistics of a project's delivery process are managed by experienced, empowered project management personnel who have received extensive training and years of on-the-job experience before being entrusted to lead a project. Our people understand the critical importance of delivering on time and budget. With this expertise in -house we have delivered several projects in the USA one of which being 263, 34th Street New York tower which is right across the iconic Empire State Building.

Call us

+91-9028464755Mail us

sales@alumayerindia.com contracts@alumayerindia.com